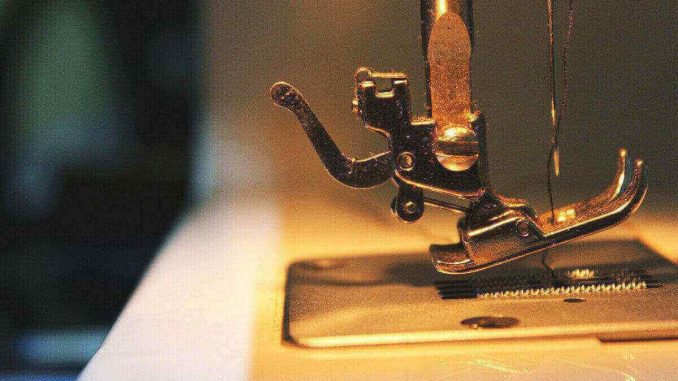

In the intricate world of garment production, the backbone of precision lies in the sewing machines used. Importing sewing machines can be a game-changer for businesses seeking quality, efficiency, and a competitive edge. This comprehensive guide explores the nuances of importing sewing machines, covering everything from understanding market trends to navigating regulations and making informed decisions that can positively impact your sewing operations.

Market Trends and Demand Analysis

Market Trends and Demand Analysis

Before delving into the process of importing sewing machines, it’s crucial to understand the current market trends and assess the demand for specific types of machines. Analyze the sewing industry’s landscape, identify emerging technologies, and consider the preferences of your target market. This insight will guide your decision-making process and ensure that the imported machines align with industry demands.

Research Reliable Suppliers

Choosing the right supplier is paramount when importing sewing machines. Research and vet potential suppliers based on their reputation, product quality, and reliability. Consider factors such as manufacturing standards, certifications, and customer reviews. Building a strong relationship with a reputable supplier sets the foundation for a successful and sustainable import venture.

Compliance with Regulations

Importing sewing machines involves navigating a maze of regulations, tariffs, and compliance requirements. Familiarize yourself with the import regulations of your country and the specific requirements for sewing machines. This may include safety standards, labeling requirements, and certification processes. Ensuring compliance from the outset will prevent delays and potential legal issues down the line.

Customs Duties and Tariffs

Understanding customs duties and tariffs is a critical aspect of the importing process. Different countries impose varying duties on imported goods, and sewing machines may fall under specific tariff classifications. Consult with customs authorities or engage a customs broker to determine the applicable tariffs for your imported sewing machines. Accurate tariff calculations are essential for budgeting and pricing considerations.

Quality Standards and Certifications

Sewing machines must adhere to specific quality standards and certifications to ensure safety, performance, and durability. Research international quality standards such as ISO certifications and product-specific certifications. Verify that the sewing machines you plan to import meet these standards. Having certified machines not only assures your customers of product quality but also streamlines the customs clearance process.

Shipping Logistics

Efficient shipping logistics are crucial for timely deliveries and cost-effective imports. Consider factors such as shipping methods, container sizes, and transportation modes. Optimize your shipping strategy to minimize transit times and reduce freight costs. Collaborate with reputable freight forwarders to handle the logistics, ensuring that your sewing machines reach their destination securely and on schedule.

Documentation Requirements

Accurate documentation is the backbone of successful imports. Ensure that you have all the necessary paperwork, including commercial invoices, packing lists, bills of lading, and certificates of origin. Familiarize yourself with the specific documentation requirements of your country and the exporting country. Proper documentation facilitates smooth customs clearance and mitigates the risk of delays.

Consideration of Voltage and Compatibility

Consideration of Voltage and Compatibility

Sewing machines often come with specific voltage requirements. Before importing, verify that the machines are compatible with the electrical standards of your country. Addressing voltage and compatibility issues in advance prevents operational disruptions and the need for costly modifications or additional equipment.

After-Sales Support and Warranty

Evaluate the after-sales support and warranty offerings provided by the sewing machine supplier. A reliable supplier should offer comprehensive support, including technical assistance, spare parts availability, and warranty coverage. Investing in machines with robust after-sales support enhances the longevity and reliability of your sewing operations.

Training and Skill Development

Introducing new sewing machines may require training for your workforce to maximize efficiency and output. Consider the availability of training programs offered by the supplier or third-party training providers. Investing in the skill development of your team ensures that they can harness the full potential of the imported sewing machines.

Conclusion

Importing sewing machines can revolutionize your garment production processes, providing efficiency, precision, and access to cutting-edge technology. By understanding market trends, researching reliable suppliers, ensuring regulatory compliance, and optimizing shipping logistics, you can embark on a successful journey of importing sewing machines. Remember, informed decisions and meticulous planning are the stitches that hold together a seamless and prosperous import venture. Whether you are a small-scale tailor shop or a large-scale garment manufacturer, the careful consideration of every aspect of the importing process will position you for success in the dynamic world of sewing machine imports.

Leave a Reply