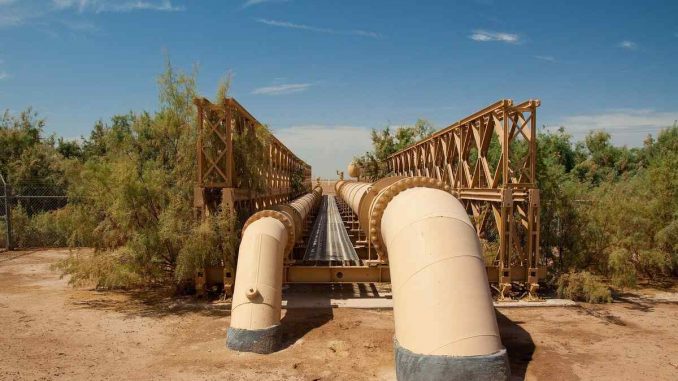

In the world of modern infrastructure, pipelines are the backbone of industries like oil, gas, water, and other essential utilities. As pipelines crisscross cities, countries, and even oceans, the need for robust pipeline leak detection systems has never been greater. Whether transporting natural gas to homes, supplying water to cities, or moving crude oil across vast distances, pipeline integrity is crucial for environmental safety, economic efficiency, and public health. In this article, we will delve into the methods, importance, and technologies associated with pipeline leak detection, ensuring your infrastructure operates at optimal safety levels.

The Importance of Pipeline Leak Detection

Pipeline leak detection is more than just a safety measure; it is a key component in reducing environmental damage, saving costs, and maintaining efficient operations. Undetected leaks can result in a range of consequences, from environmental disasters such as oil spills and water contamination to financial losses due to product wastage and unplanned downtime. For industries operating pipelines, the question is not if a leak will occur, but when. Effective leak detection systems are a proactive step in reducing the risks associated with pipeline leaks.

- Environmental Protection: Pipelines often traverse environmentally sensitive areas like forests, wetlands, and oceans. A leak in these regions can cause significant ecological damage, including pollution of water sources, destruction of habitats, and harm to wildlife. Quick detection minimizes the amount of product spilled, limiting its environmental footprint.

- Economic Impact: For industries, pipeline leaks mean product loss. Whether it’s water or oil, a leak means the product is not reaching its destination, leading to wastage. Moreover, repairs and clean-up efforts can incur significant costs. Early detection can prevent extensive damages and save millions in repair and legal expenses.

- Operational Efficiency: Unscheduled downtime due to a pipeline leak can be disruptive, especially for industries that depend on continuous operations, such as oil refineries or water treatment facilities. Regular monitoring of pipeline integrity ensures that leaks are detected and addressed before they cause major disruptions.

- Public Safety: Pipelines carrying hazardous materials, such as natural gas or chemicals, pose a risk to public safety. A significant leak can result in explosions, fires, or contamination of drinking water, potentially endangering lives. Detecting leaks early allows operators to mitigate such risks and take preventative actions to protect public health.

Types of Pipeline Leaks

Before discussing detection technologies, it’s important to understand the types of leaks that can occur in a pipeline:

- Small Leaks: Small leaks are harder to detect but can cause long-term damage. These types of leaks may not initially affect the overall pressure of the pipeline but can lead to corrosion or product contamination over time.

- Large Leaks: Larger leaks are more noticeable, often resulting in significant product loss, pressure drops, and sometimes catastrophic failures, like pipeline bursts.

- Pinhole Leaks: Pinhole leaks are tiny and often caused by corrosion, equipment defects, or external damage. Despite their small size, pinhole leaks can have severe consequences if they go undetected over a prolonged period.

Pipeline Leak Detection Methods

The approach to leak detection varies based on the type of pipeline, the material being transported, and the environmental conditions. Below are the main methods used in detecting pipeline leaks:

1. External Leak Detection Systems

External leak detection methods are based on the use of sensors or monitoring devices placed along the pipeline to identify leaks. These sensors detect changes in the surrounding environment or the pipeline itself that may indicate a leak.

- Acoustic Monitoring: Acoustic sensors detect the sound waves produced by a leak. As fluid escapes a pipeline under pressure, it creates vibrations that can be picked up by these sensors. This method is effective in detecting both small and large leaks but requires a well-calibrated system to differentiate between normal operational noise and leaks.

- Infrared Sensors: Infrared cameras or sensors are used to detect temperature differences around the pipeline, which can indicate a leak. For example, a gas leak may create a cooling effect that is detectable by infrared technology.

- Fiber Optic Cables: Fiber optic cables placed along the length of a pipeline can detect changes in temperature, pressure, and strain. These systems provide real-time monitoring and are highly sensitive, making them effective in detecting even the smallest leaks.

2. Internal Leak Detection Systems

Internal leak detection methods focus on monitoring the flow, pressure, and temperature of the product being transported within the pipeline.

- Pressure Monitoring: Pressure sensors inside the pipeline can detect drops in pressure, which is often an indication of a leak. A rapid drop in pressure may signify a large leak, while a slow decline could indicate a small or pinhole leak.

- Flow Monitoring: Flow meters installed at various points along the pipeline monitor the amount of product passing through. Any significant discrepancies between the input and output flows may indicate a leak.

- Mass Balance Systems: This method compares the mass of fluid entering and exiting the pipeline. If a difference is detected, it suggests that some of the product has leaked from the pipeline.

3. Visual Inspection and Drone Technology

Advancements in drone technology have made visual inspections more efficient. Drones equipped with cameras or infrared sensors can fly over pipelines, capturing real-time data and identifying leaks from visual anomalies like oil slicks or gas clouds. This method is particularly useful in remote or hard-to-access areas, offering a fast and cost-effective solution.

4. Computational Pipeline Monitoring (CPM)

CPM uses algorithms to monitor data collected from the pipeline’s sensors, such as pressure, temperature, and flow. By analyzing this data, CPM systems can detect anomalies that may indicate a leak. These systems are continuously improving with advancements in artificial intelligence (AI) and machine learning, which allow for more accurate detection of leaks and prediction of potential failures.

Challenges in Pipeline Leak Detection

While numerous methods exist, pipeline leak detection comes with its own set of challenges:

- False Alarms: Leak detection systems can sometimes trigger false alarms due to environmental factors or system malfunctions, leading to unnecessary shutdowns or costly inspections.

- Environmental Conditions: In challenging environments, such as deep-water pipelines or those in extreme climates, detection systems may be less effective. Equipment must be designed to withstand harsh conditions while still providing accurate readings.

- Cost of Implementation: While leak detection systems are essential, installing and maintaining them can be expensive, especially for older pipelines that were not originally equipped with these technologies. However, the long-term benefits in terms of avoided environmental fines, product loss, and operational downtime often outweigh the initial costs.

The Future of Pipeline Leak Detection

The Future of Pipeline Leak Detection

As technology continues to evolve, the future of pipeline leak detection looks promising. Newer systems are leveraging AI, machine learning, and advanced sensor technologies to provide faster, more accurate leak detection. Automated systems, such as drone surveillance, are becoming more prevalent, reducing the need for manual inspections.

Moreover, predictive maintenance systems are gaining traction. Instead of reacting to leaks after they occur, companies are increasingly focusing on predicting when and where leaks are likely to happen, allowing for proactive maintenance before any damage occurs.

In conclusion, pipeline leak detection is a critical aspect of infrastructure management. With the right systems in place, industries can mitigate the risks of environmental damage, reduce financial losses, and ensure the safety of both the public and the environment. Whether through external sensors, internal monitoring, or cutting-edge drone technology, leak detection is essential for the safe and efficient operation of pipelines in today’s world.

Leave a Reply