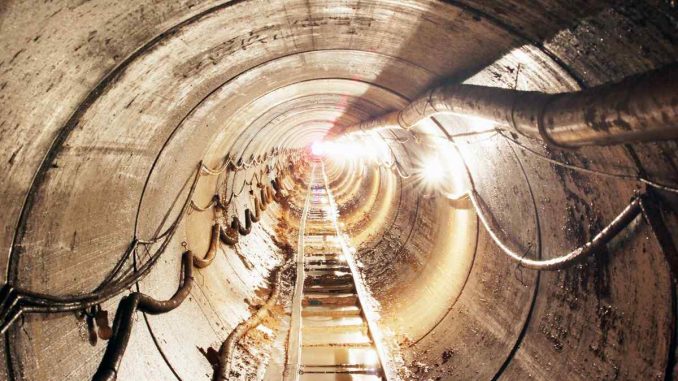

Microtunneling is a trenchless construction method used to install pipelines with minimal surface disruption. This innovative technique has revolutionized underground construction, offering a cost-effective and environmentally friendly alternative to traditional open-cut methods. In this article, we’ll explore the principles of microtunneling, its key components, and the various techniques used in this cutting-edge technology.

What is Microtunneling?

What is Microtunneling?

Microtunneling is a trenchless construction method used to construct small diameter tunnels for the installation of pipelines, conduits, and cables.

Unlike traditional open-cut methods, microtunneling requires minimal excavation and surface disruption, making it ideal for urban areas and environmentally sensitive locations.

Microtunneling is typically used for the installation of sewer, water, and utility pipelines, as well as for various infrastructure projects.

Key Components of Microtunneling

- Microtunnel Boring Machine (MTBM): The MTBM is the central component of the microtunneling system. It is a remote-controlled machine that excavates the tunnel and installs the pipeline simultaneously.

- Launch Shaft: The launch shaft is the starting point for the microtunneling operation. It is used to lower the MTBM into the ground and provide access for personnel and equipment.

- Reception Shaft: The reception shaft is the endpoint for the microtunneling operation. It is used to retrieve the MTBM and provide access for pipeline installation and inspection.

- Guidance System: The guidance system is used to steer the MTBM and ensure that the tunnel is excavated along the desired alignment and grade.

- Pipe Jacking System: The pipe jacking system is used to push or pull the pipeline into the tunnel as it is excavated by the MTBM.

Microtunneling Techniques

- Pilot Tube Microtunneling: In this technique, a pilot tube is first installed along the desired tunnel alignment using a guided boring machine. The pilot tube serves as a guide for the MTBM, which follows the pilot tube path while excavating the tunnel.

- Slurry Microtunneling: Slurry microtunneling involves the use of a slurry to stabilize the tunnel face during excavation. The slurry also helps to transport excavated material back to the surface.

- Earth Pressure Balance (EPB) Microtunneling: EPB microtunneling uses the excavated material to create a balanced pressure in the tunnel face, preventing ground settlement and surface disruption.

- Auger Boring: Auger boring is a technique used to install pipelines in stable soil conditions. It involves the use of an auger to excavate the soil and a casing to support the tunnel walls.

Benefits of Microtunneling

Benefits of Microtunneling

- Minimal Surface Disruption: Microtunneling requires minimal excavation and surface disruption, making it ideal for urban areas and environmentally sensitive locations.

- Cost-Effective: Despite its initial costs, microtunneling can be more cost-effective than traditional open-cut methods due to reduced labor, equipment, and restoration expenses.

- Versatility: Microtunneling can be used for a wide range of applications, including sewer, water, and utility pipelines, as well as for various infrastructure projects.

- Reduced Environmental Impact: Microtunneling reduces the environmental impact of construction by minimizing disruption to surface features, wildlife habitats, and natural resources.

Conclusion

Microtunneling is a cutting-edge technology that has revolutionized underground construction. By minimizing excavation and surface disruption, microtunneling offers a cost-effective and environmentally friendly alternative to traditional open-cut methods. With its versatility and efficiency, microtunneling is poised to play a significant role in the future of underground construction.

Leave a Reply