In today’s rapidly evolving manufacturing industry, precision and efficiency are paramount. CNC (Computer Numerical Control) machines have revolutionized the way we produce parts and components across various sectors. In this article, we will explore the diverse world of CNC machines, shedding light on different types and their applications.

What Are CNC Machines?

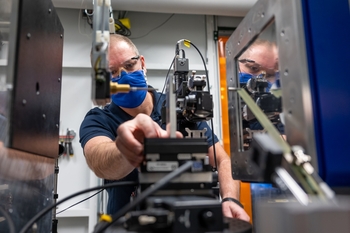

CNC machines are automated tools that use computer programming to control and execute precise machining operations. These machines offer unparalleled precision, repeatability, and versatility in manufacturing processes. By eliminating the need for manual operation, CNC machines enhance productivity and reduce the margin of error, making them indispensable in industries like aerospace, automotive, medical, and more.

Now, let’s delve into various types of CNC machines:

CNC Milling Machines

CNC Milling Machines

CNC milling machines are among the most common and versatile types of CNC machines. They employ rotating cutting tools to remove material from a workpiece, producing complex shapes and designs with high precision.

CNC milling machines are capable of three, four, or even five-axis operations, allowing for intricate machining of materials like metals, plastics, and composites.

Applications:

- Creating precision mechanical components

- Aerospace part production

- Mold and die manufacturing

- Prototype development

CNC Lathe Machines

CNC lathe machines, also known as turning centers, are used for cylindrical part machining. They secure a workpiece in a chuck or collet and rotate it while a cutting tool shapes it symmetrically. CNC lathes are ideal for producing cylindrical parts, including shafts, bolts, and screws, with precision and efficiency.

Applications:

- Manufacturing of bushings and sleeves

- Production of threaded components

- Turning operations in the automotive industry

- Aerospace industry for turbine components

CNC Router Machines

CNC router machines are specially designed for cutting, engraving, and shaping materials such as wood, plastic, and foam. They use various types of cutting tools, including bits and end mills, to create intricate designs and patterns on flat workpieces. CNC routers are popular in the woodworking, signage, and artistic industries.

Applications:

- Woodworking and cabinetry

- Sign making and engraving

- Foam and plastic prototyping

- Artistic carving and sculpture

CNC Plasma Cutting Machines

CNC plasma cutting machines are used for precise and efficient metal cutting, primarily for materials like steel, aluminum, and stainless steel. These machines employ a high-velocity jet of ionized gas (plasma) to melt and remove metal, guided by CNC controls. CNC plasma cutters are widely used in industries requiring accurate metal profiling.

Applications:

- Metal fabrication and manufacturing

- Automotive and aerospace component cutting

- HVAC ductwork fabrication

- Construction and architectural metalwork

CNC Laser Cutting Machines

CNC laser cutting machines utilize focused laser beams to cut, engrave, or mark a wide range of materials, including metals, plastics, and ceramics. They offer high precision and speed, making them ideal for intricate and intricate designs.

Applications:

- Sheet metal cutting for automotive parts

- Precision cutting of jewelry and medical devices

- Architectural and decorative metalwork

- Prototyping and small-scale production

CNC EDM Machines (Electrical Discharge Machining)

CNC EDM machines use electrical discharges to shape and cut conductive materials with high precision. They are particularly valuable when working with hard materials that are challenging to machine with traditional methods. CNC EDM machines come in two primary types: Wire EDM and Sinker EDM.

Applications:

- Tool and die production

- Mold making for plastic injection

- Aerospace turbine blade manufacturing

- Medical device manufacturing

CNC Swiss Machines

CNC Swiss machines, also known as Swiss lathes or Swiss screw machines, are designed for high-precision and high-volume manufacturing of small, intricate parts. They excel at producing components with tight tolerances and complex geometries.

Applications:

- Watchmaking and watch components

- Medical device manufacturing

- Aerospace miniature parts

- Electronics and telecommunications components

CNC 3D Printers

CNC 3D Printers

CNC 3D printers combine CNC machining and additive manufacturing techniques. They use a variety of materials, including plastics, metals, and ceramics, to build 3D objects layer by layer.

CNC 3D printers are gaining popularity in rapid prototyping and low-volume production.

Applications:

- Prototyping of complex components

- Custom jewelry and fashion accessories

- Dental prosthetics and orthopedic implants

- Aerospace and automotive part development

Conclusion

The world of CNC machines is diverse and continuously evolving, offering a wide array of options to meet the demands of various industries. From CNC milling machines that create intricate metal components to CNC routers crafting detailed woodwork, these machines have revolutionized manufacturing processes.

CNC machining in Perth and around the world has become synonymous with precision engineering. By understanding the different types of CNC machines and their applications, manufacturers can make informed decisions about which technology best suits their needs, ensuring they stay at the forefront of modern manufacturing.

Leave a Reply